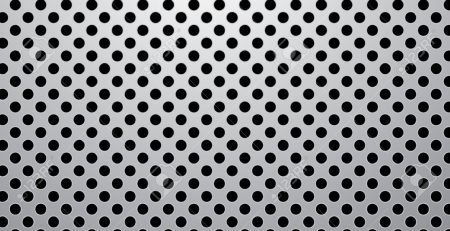

Perforated Metal

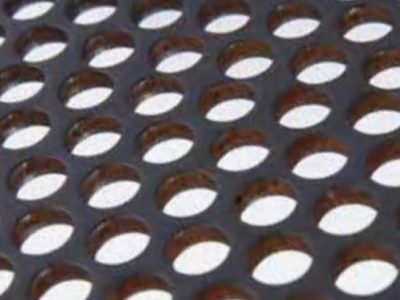

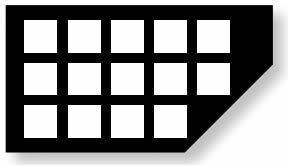

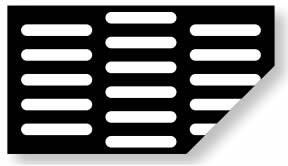

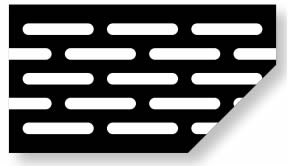

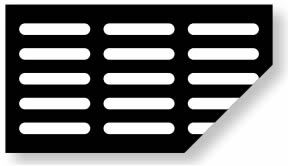

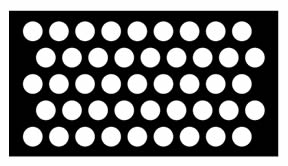

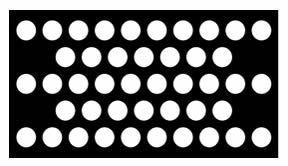

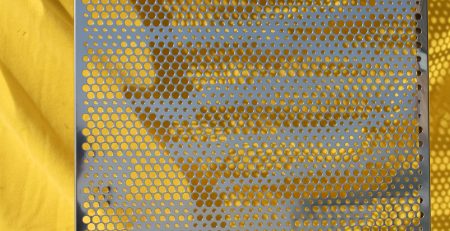

The perforated sheets are produced by special machinery and formwork; through perforating the Cupper, Steel, Stainless Steel, Aluminium and similar metal sheets with various hole types, diameters, center arrangements.

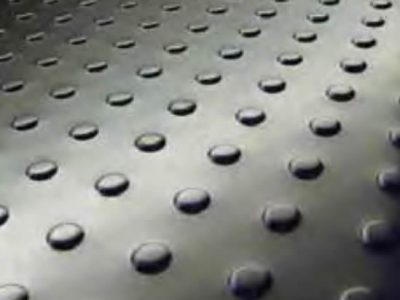

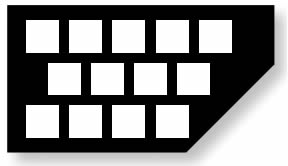

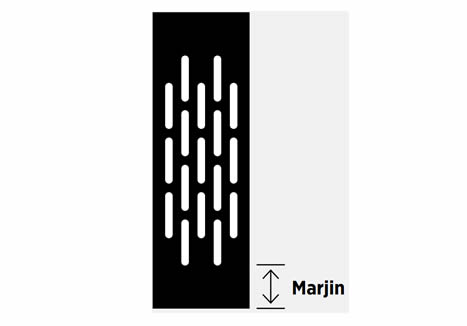

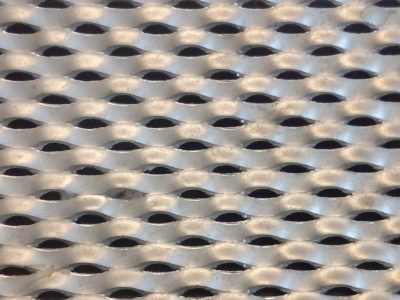

The punched parts could be used as well as the perforated sheets itself. The hole may be at the same leveling with the original sheet, while it can also be embedded or embossed accordingly. Embedding or embossing may be performed without making a hole. The arrangement of the holes may be in-line or staggered at a requested angle. At the beginning, at the end or at the sides of the sheet, there can be margins without perforation. The advantages are, lightweight, light transparency, control of heat transfer, anti-skid possibilities, aqouistic efficiency. Durability, few maintenence and cleaining necessity leads perforated metal to be used widely at internal architecture, HVAC and noise insulation systems, at suspended ceilings and various floorings, fences and screens, building facades, sun shaders and many others.